CLEANING & CONDITIONING

CLEANING

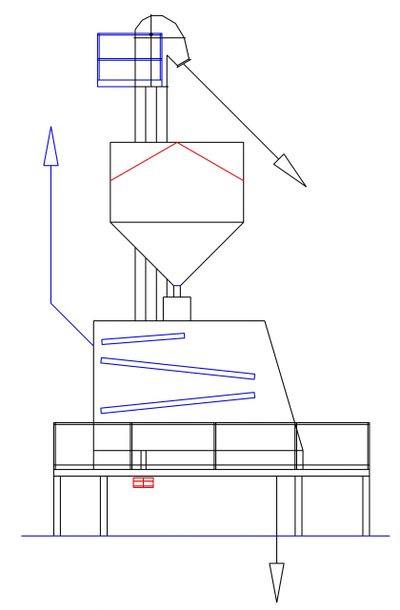

Delinted cottonseed is fed through an air / screen cleaner. The seeds move across perforated vibrating screens with various openings. In the cleaner, air is introduced to carry away the light particles. The air steam removes the dust and light trash.Sticks, heavy trash and cull seeds are separated from the good seed through the screen perforations.

GRAVITY SEPARATION

The gravity table separates the seeds by density. The immature and cracked seeds are lighter and gather at one outlet of the table. Heavier seeds are most likely to successfully germinate and are accumulated at the upper end of the table. Air flow allows the seed bed to float thereby reducing friction. The vibrating action of the table steers each seed to the proper outlet.

TREATING

Seed Treatment Chemicals are applied in state of the art application equipment. Only the best seeds are coated with a precise slurry of chemicals designed to fight pests and bacteria that may inhibit germination or hinder early stages of growth. The applied coating is dried and polished to create a nice, free flowing seed with all the advantages that modern chemistry can provide.

Copyright © 2024 Jerry Forburger LLC - All Rights Reserved.

Powered by GoDaddy

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.